- HOW TO CUT SINGLE LINES IN SHEETCAM PRO

- HOW TO CUT SINGLE LINES IN SHEETCAM SOFTWARE

- HOW TO CUT SINGLE LINES IN SHEETCAM CODE

HOW TO CUT SINGLE LINES IN SHEETCAM SOFTWARE

Some people may be used to or comfortable with other design software so your not limited in that regard with Design2Cut. You can still use other CAD design programs and import the drawings into Design2Cut. With Design2Cut all of this happens in one place and one program. You can see this process was time consuming and if you ran into a problem with a cut you had 3 placed you need to check to find the problem and correct it.

HOW TO CUT SINGLE LINES IN SHEETCAM CODE

Then we opened a program called Mach3 and imported the G- Code file from Sheetcam. We processed the part in the CAM software then ran a post processor to turn it into G- Code. Then we opened a program called Sheetcam and imported our drawing. In our last machine we would use our CAD program ie, Corel or Drawplus to create the part or artwork we wanted to make. This greatly simplifies the task of making something.

Meaning that it can take the place of three programs and allow you to build a CAD part, Complete CAM processing and send it to the Machine for cutting all in one program. What is unique with Design2Cut is that it is an all in one solution for your software. While this program is proprietary to Westcott Plasma it can be adapted and used with other brands of machine and can be retrofitted to machines using other software options.

HOW TO CUT SINGLE LINES IN SHEETCAM PRO

Ultimately check with your machines manufacture and the CAM software manufacture to ensure compatibility with your system.įor our Pro Series plasma table from Westcott Plasma we are using Design2Cut for our CAM program. There are many sites available on the Internet where you can get or purchase artwork ready to go like here at: Unique info can include the size and configuration of your steppers or servos, machine table size, plasma cutter and its settings, design of your table, Z axis setup, accessories like air scribes, or rotary devices. dxf files then process them in your CAM software and export them to your machine. Instead you can trade or use other peoples. Trading G- Code files is not recommended the results are most likely not going to work. For more info on G- Code click HERE: The reason CAM software and the G- Code that it generates can not be moved from machine to machine is that these software components have specific information that is unique to your machine and its setup.

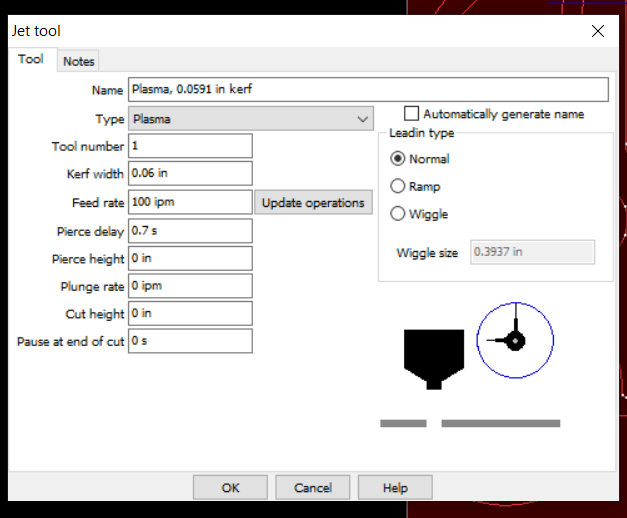

G- Code is the language the machine speaks. The CAM program usually will create some form of G- Code To accomplish this. Each of these vary from program to program but most will automate this very complex process into some thing very simple that can be done with just a few clicks after the program has been populated with all of your machine variables during initial setup. There are litteraly hundreds of variables that CAM program will control. The CAM program is going to take all of the settings you have picked for your material, the thickness, as well as all of the information from your drawing and turn that into something that the machine can use to complete the task and make your object. Unlike the artwork software the CAM software must be programmed to specifically match up to the table, control system and plasma cutter.

Many of the higher end and industrial tables come with a proprietary CAM software. For DIY systems, hobby grade and many of the kit form tables Sheetcam brand CAM software is one of the most popular. There are nearly as many CAM programs available as there are Artwork Programs. The capabilities and design of your table as well as the material that you use can vary slightly so a little tweaking to the settings may be necessary for your application but the cut charts from Hypertherm are a great place to start and have all the info that you need. There settings are based on ideal circumstances with brand new consumables. They have all the specifications and settings informational for nearly every material that you would ever cut.

Hypertherm does an excellent job of testing and evaluating materials and machine settings to perfect them. Most of the other values will have been set up previously or settings can be imported to match your plasma cutter. Most of the settings and operations will be automated to some degree here and can be as simple as picking the material and thickness. CAM - Computer Aided Machining is where were going to set up the cut by telling the machine what were cutting (Aluminum, Steel, Stainless Steel ect.) How thick the material it is and setting up our lead in and outs, cutting amps and speed and host of other data. CAM Software is the software that takes your CAD drawing or artwork that you want to cut and gets it ready for the machine.

0 kommentar(er)

0 kommentar(er)